Unrivaled Expertise in Remanufacturing Power Control Systems

Original equipment manufacturers (OEMs) of turbine and industrial control systems continually urge power plants to stay up-to-date with technology by upgrading their machinery. Though OEMs’ purpose is to improve equipment associated with the turbine control system, they unintentionally burden clients with avoidable extra costs.

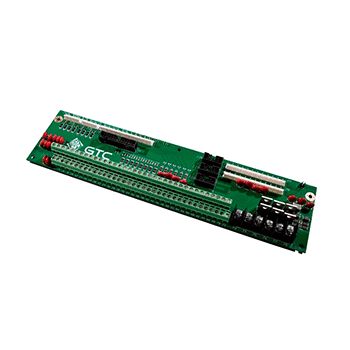

To this end, GTC Control Solutions (GTC) helps power plants save significant money and time by offering quality alternatives for customers forced into upgrading their controls, protection, and monitoring systems due to OEM obsolescence plan. A leader in obtaining, testing, and supplying replacement parts for any control system, GTC supports clients by extending the life of legacy equipment, preventing costly substitutions or renewals.

“Our organization has the skill sets, financial investment in inventory, product quality, and repair services capabilities that enable customers to save significant time and money by avoiding the upgrades to the latest model,” says John P. SantaCroce, President and COO, GTC.

Contrary to uninformed preconceptions, remanufactured products are not old or unreliable. They are often better than a seemingly new component that might be sitting on a shelf for over 10 years. GTC proactively changes individual key components of the part and upgrades them to improved versions of the originally manufactured ones. This cost-effective approach benefits power plant owners facing increased lead times for new products due to pandemic-induced supply chain delays.

With GTC’s remanufactured and warranted products, clients in need of immediate replacement parts can get up and running within a week and save millions of dollars due to reduced or no downtime. Changing all the key components, the company provides clients with the benefits of almost new parts at a lower cost without compromising on quality.

GTC’s warranty claim rates are a testament in itself to the quality of their products. They offer three years warranty on remanufactured products and has less than one percent warranty claims. GTC also has extensive inventories of parts for turbine control systems discontinued or obsoleted by the OEM in unused, remanufactured, or repaired conditions.

While interacting with clients, GTC digs deeper into their requirements and pain points by asking the right questions related to expansion and upgrades. Their technicians have the expertise to diagnose problems quickly and efficiently. GTC’s agile field service engineers assist clients in effectively maintaining controls through troubleshooting, preventative maintenance, and outage support.

For instance, a paper mill client who operates a GE Mark IV turbine control system was looking for upgrade options. Since the production of these systems had stopped in 1991, the client was convinced of its obsolescence and wanted to bring in a state-of-the-art system. GTC, upon engaging with the client, assured them to keep their existing systems by quickly refurbishing and enhancing their efficiency.

Keeping the existing systems refrained the client from spending time and resources on training employees on a new system. They did not have to go through three plus weeks of downtime, saving them around two million dollars. Similarly, GTC helped another client enhance the performance of their GE Mark V system and save significant upgrade costs.

These are just a few examples of GTC’s competencies. Customers constantly return to GTC due to their demonstrated responsiveness, expertise, and services and in parts for all models of the turbine, generator, excitation, and LCI controls, as well as HMI and vibration monitoring. To keep the wheel spinning, GTC’s business development team constantly reaches out to prospects and convinces them of the value the company can bring them. New customers are handed off to the sales department that manages all the transactions and provides clients with the components for the systems or services they need.

Being ISO 9001 Certified helps “Our team keeps track of customer needs through all stages, from the lab to the warehouse, and the inbound sales team to the accounts department. This helps us follow a client-centric approach that drives our on-time delivery performance to 95 percent and brings down warranty claims rate to under one percent,” adds SantaCroce.

Enabling the end user to get the most out of their equipment, GTC is also spearheading environmental stewardship through their green initiative. They are preventing the wastage of old products by keeping legacy systems up and running for years with improved efficiency.

To view the full article, please visit here!